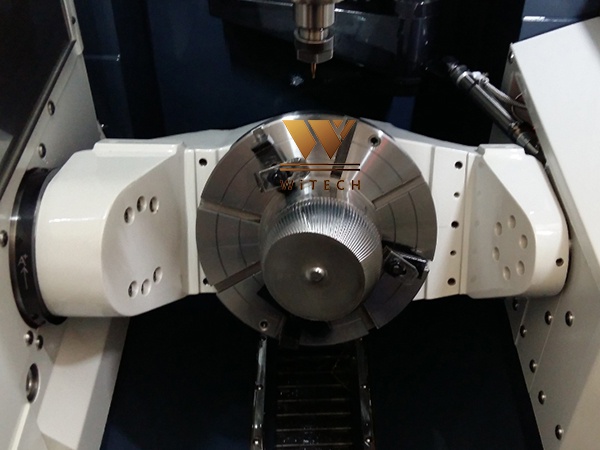

CNC milling services

Our engineers are proficient in using CNC milling equipment and professional software for 3-axis, 4-axis, and 5-axis machining. Therefore, whether the components you design are made of metal or insulation materials, we can meet your manufacturing needs

We can provide real-time quotations and fast delivery, and provide manufacturability design feedback for the components you design

Advantages of CNC milling services I

Quick Delivery: We use a new type of CNC milling machine equipment that can quickly produce high-precision components within 10 days

Processing Precision: Processing precision control complies with multiple tolerance options of ISO 2768 (standard level, fine level) and ISO 286 (levels 8, 7, 6)

Customized Surface Treatment: You can choose various surface treatment methods suitable for metal and plastic parts according to your own design, and manufacture the appearance design requirements that meet your parts

Advantages of CNC milling services II

Processing Material Selection: You can choose different metal materials and insulation materials to process components

Machining Dimensions: We can provide CNC turning and milling components with maximum machining dimensions of X axis 3800mm, Y axis 8000mm, and Z axis 1700mm

Quality Control: Our quality assurance department implements strict quality assurance processes

Material I for CNC milling

Aluminum alloy materials: Aluminum alloy 6061, aluminum alloy 5052, aluminum alloy 2A12, aluminum alloy 7075

Stainless Steel: Stainless Steel 303, Stainless Steel 304, Stainless Steel 316, Stainless Steel 316L, Stainless Steel 420, Stainless Steel 430, Stainless Steel 17-4PH, Stainless Steel 301, Stainless Steel 321

Alloy steel: Q235 (A3 steel), 45 steel, Cr12, 3Cr13, GCr15, 40Cr, spring steel-65Mn, mold steel-SKD11,

Copper alloy: Brass-H59, Brass-H62, Purple Copper-T2, Oxygen free Copper TU2, Tin Bronze QSn-6-6-3, Beryllium Copper-C17200

Material II for CNC milling

Other alloys: Electrical pure iron-DT4C, Electrical pure iron-DT4E, Titanium alloy-TC4, Magnesium alloy-AZ91D

Plastics: Engineering plastics ABS, polytetrafluoroethylene PTFE, Saigang POM, bakelite, organic glass PMMA, polypropylene PP, polyphenylene sulfide PPS, polyurethane PU (adhesive), polyvinyl chloride PVC, epoxy board FR4, polyethylene HDPE, polyethylene LDPE, nylon PA6, nylon PA66, polycarbonate PC, polyether ether ketone PEEK,

Special materials and others: Carbon fiber board, graphite